Fastener Expo Shanghai | Understanding Core Fastener Equipment: Drawing Machines and Hot Forging Machines

As manufacturing continues to move toward high-end, large-scale and intelligent development, fasteners—one of the most fundamental and widely used industrial components—are attracting increasing attention for their production processes and equipment systems. From wire rod preparation and high-speed forming to heat treatment and surface finishing, every step directly affects product consistency, reliability and manufacturing cost.

Fastener Expo Shanghai 2026, the 16th edition of the show, will take place on June 24–26, 2026 at the National Exhibition and Convention Center (Shanghai). As a key global platform for technical and commercial exchange in the fastener industry, Fastener Expo Shanghai (FES) focuses on manufacturing equipment, processes and applications, providing an integrated communication channel for the entire supply chain. Among the core topics, drawing machines and hot forging machines have become essential areas of interest for industry professionals.

After fifteen successful editions, FES has grown into one of the “Top Three Fastener Exhibitions in the World.” It sets benchmarks in exhibitor quality, product structure, technical forums, international buyer attendance and on-site business volume. In 2025, it became the world’s largest fastener exhibition by scale. The concentrated display of drawing, cold heading and hot forging equipment continues to deepen the industry’s understanding of the fundamentals of fastener manufacturing.

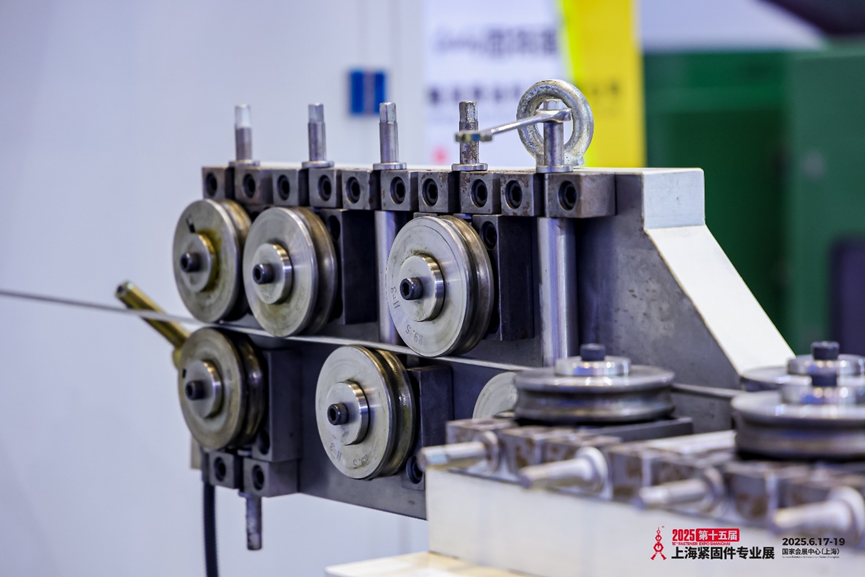

Drawing Machines: The First Critical Step in Fastener Production

A drawing machine is an indispensable piece of equipment in the fastener manufacturing chain. Its core function is to reduce steel wire rod or coarse wire to the required diameter through plastic deformation, providing qualified material for subsequent cold or hot heading. More than 90% of bolts, screws and rivets must go through the drawing process before forming.

Drawing not only changes the wire diameter but also enhances material strength and dimensional stability, which directly determines final product quality. It is widely recognized that over half of the wire’s surface quality, dimensional consistency and microstructural stability are defined at the drawing stage.

Main Types of Drawing Machines and Their Applications

Water Tank Type Drawing Machines

Featuring good cooling performance and compact structure, they are suitable for stable drawing of small and medium carbon steel and stainless steel wires, widely used by small and medium-sized fastener manufacturers.

Pulley Type Drawing Machines

With mature structure and reliable operation, they offer a wide application range and are commonly configured in traditional fastener plants.

Straight-Line Drawing Machines

Known for high efficiency and high line speed, they are ideal for mass production of high-strength fastener wire, usually equipped with automatic pay-off, online cooling and centralized lubrication systems.

High-performance drawing equipment ensures tight diameter tolerances, smooth surface finish, controlled residual stress distribution and good material flow in subsequent forming. In practice, optimized drawing systems can reduce wire scrap rates by 10–20% and significantly improve forming stability.

Hot Forging Machines: Core Equipment for Large and High-Deformation Fasteners

Hot forging machines perform forming under heated conditions. When fasteners are large in size, thick in cross-section, or made of high-resistance materials, cold heading alone cannot ensure stable forming. Heating reduces deformation resistance and enables successful forging.

Hot forging machines are mainly used for:

• Large-diameter bolts, nuts and structural components

• Heavy-duty fasteners for wind power, bridges and steel structures

• Preliminary forming of alloy and special material fasteners

Compared with cold heading, hot forging is closer to traditional forging technology and requires stricter control of temperature, pressure, energy consumption and die life.

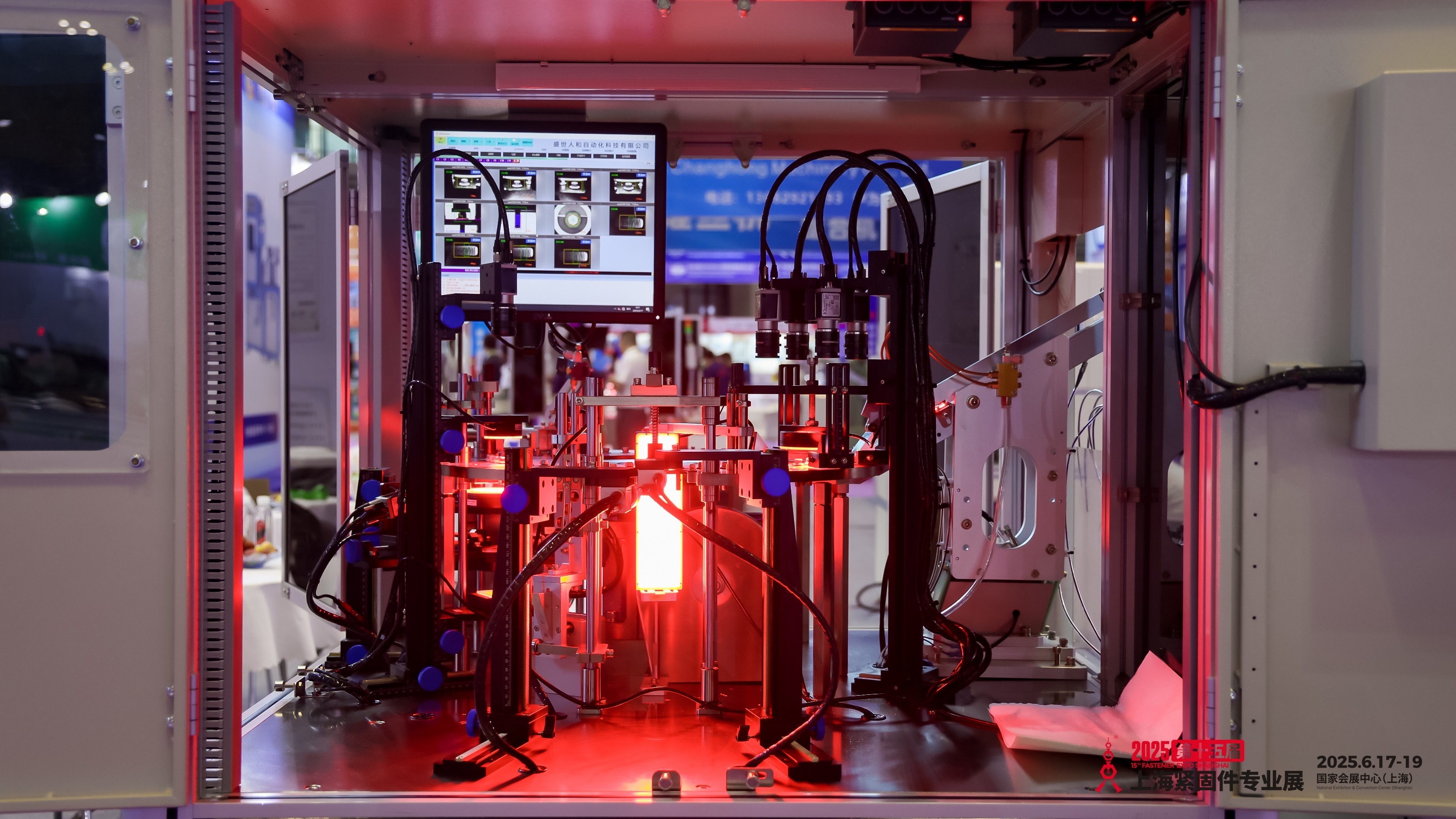

Industry Practice and Trends

Leading fastener manufacturers increasingly rely on the coordinated configuration of drawing and hot forging equipment to improve capacity and quality. By stabilizing the drawing process and precisely controlling heating and forging parameters, companies achieve systematic optimization from raw material to final forming, meeting the high reliability requirements of automotive, engineering machinery and energy industries.

As the industry moves toward high-performance and high-reliability products, equipment upgrading has become essential. In recent years, demand for advanced drawing and forging equipment in China has grown steadily, especially among producers of high-strength, stainless steel and export-oriented fasteners.

Exhibition Info:

Fastener Expo Shanghai 2026

Date: June 24–26, 2026

Venue: National Exhibition and Convention Center (Shanghai)

Scale: 70,000㎡, 1,400+ exhibitors, 25,000+ professional visitors

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~