Fastener Explained: Definition, Classification and Key Applications

In modern manufacturing and engineering, fasteners are small yet essential components, widely used in steel structures, automotive chassis, aerospace equipment, and industrial robots. They ensure the stability and safety of mechanical systems. With the trend toward high-end and precision manufacturing, performance requirements for fasteners are increasingly demanding.

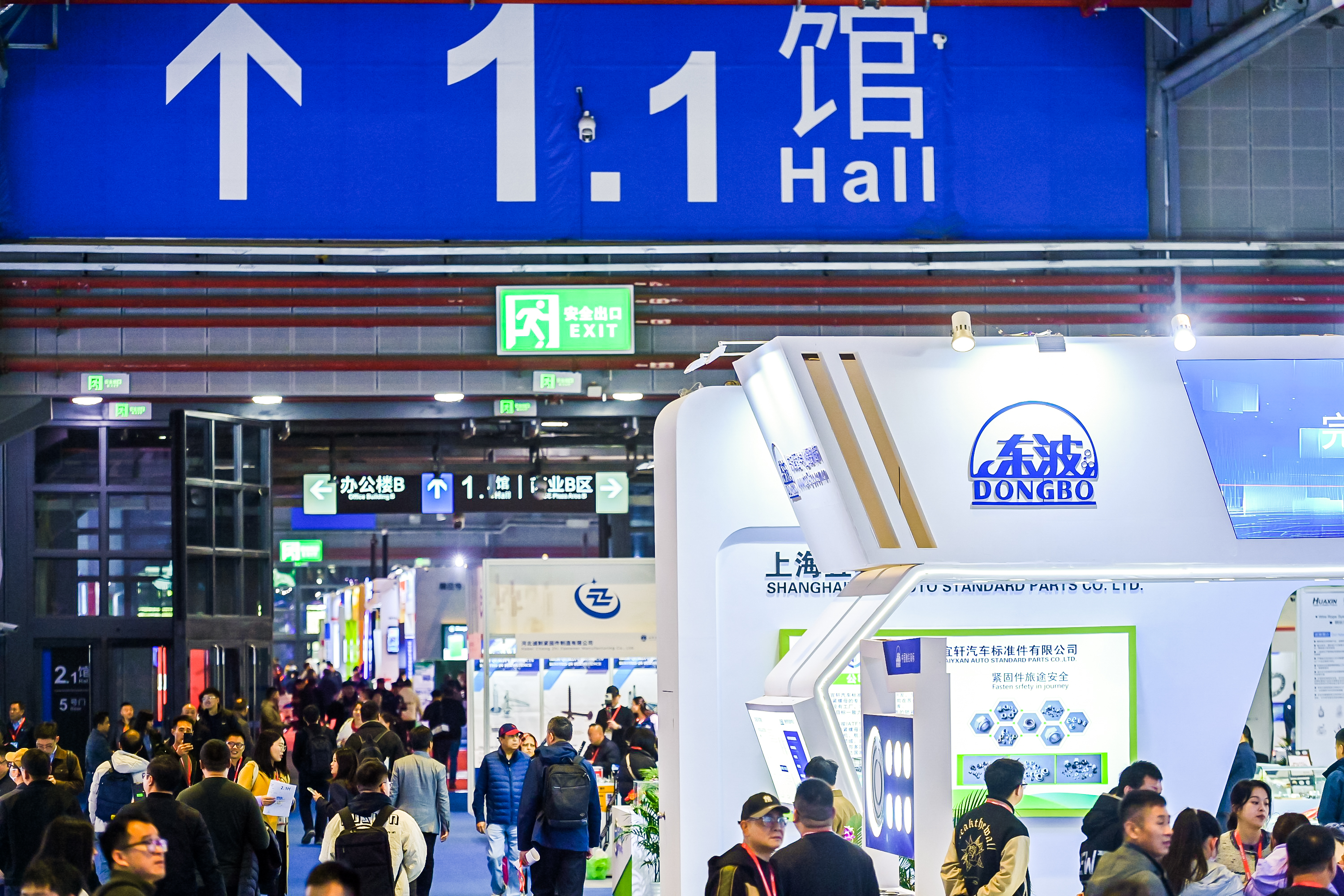

The Fastener Expo Shanghai 2026 will be held from June 24–26, 2026, at the National Exhibition and Convention Center (Shanghai). A special section, “Fastener Basics and Application Trends”, will help industry professionals understand the core value and technological developments of fasteners.

1. Definition of Fasteners

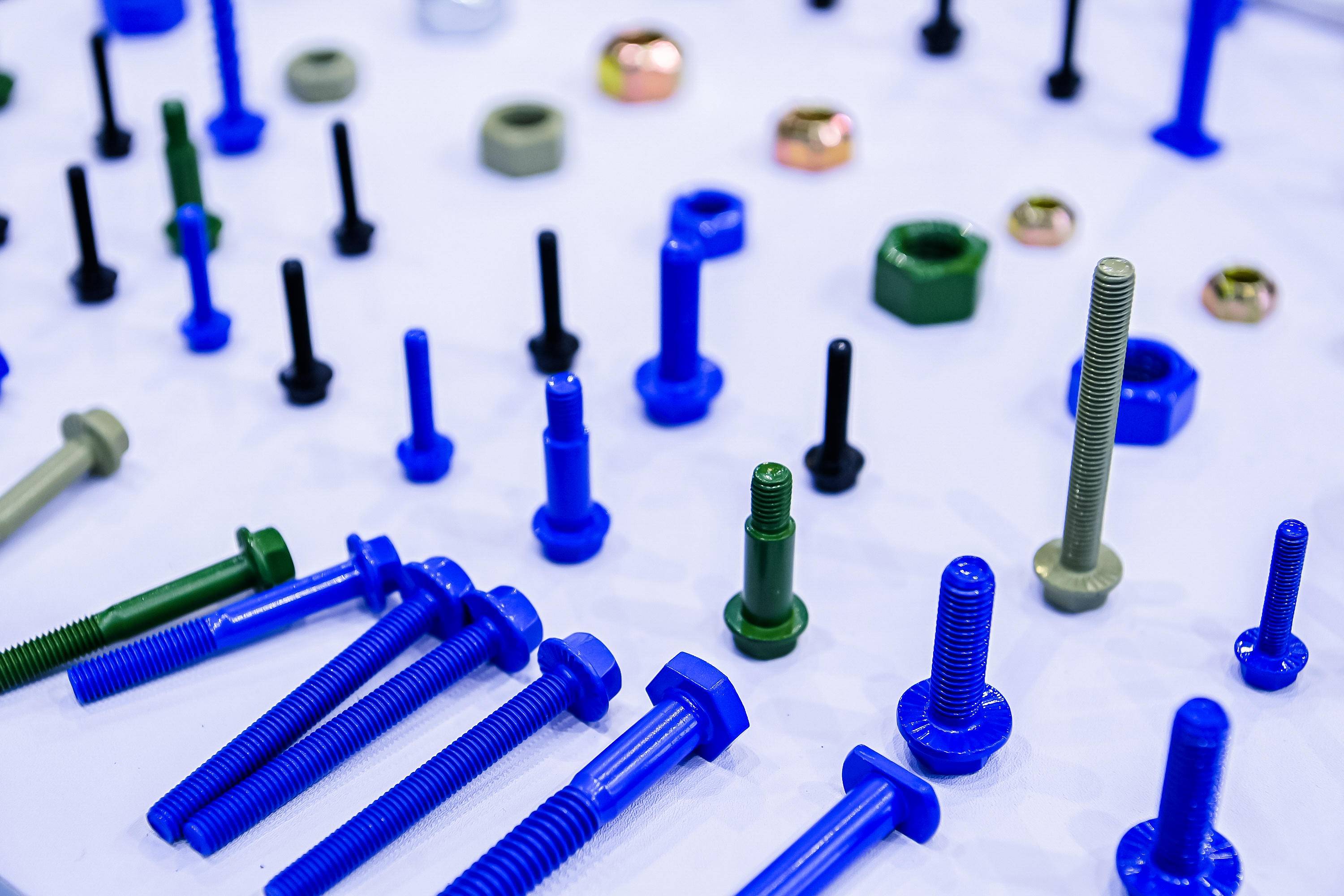

A fastener is a device used to mechanically join two or more components, usually through threads, interference fits, or extrusion. Unlike welding or adhesive bonding, most fasteners allow disassembly, facilitating maintenance and part replacement. Common fasteners include bolts, screws, nuts, washers, rivets, pins, and anchors, each serving specific assembly and engineering needs.

2. Major Categories of Fasteners

Threaded Fasteners: Bolts, screws, and nuts, providing removable connections via threaded engagement.

Riveted Fasteners: Rivets form permanent connections through deformation, widely used in aerospace, rail transit, and steel structures.

Pins and Clamps: Pins, snap rings, etc., for positioning, locking, or rapid assembly.

Anchoring Fasteners: Anchors and expansion bolts, used to secure components to concrete, masonry, or other base materials.

3. Materials and Performance

Fastener materials determine strength, corrosion resistance, and applicability:

304 Stainless Steel: Suitable for general industrial and indoor use

316 Stainless Steel: Superior corrosion resistance for coastal or chemical environments

High-strength Alloy Steel / Titanium: For aerospace, rail transit, and high-end equipment

Heat treatment, surface plating (zinc, Dacromet) or composite coatings further enhance durability and mechanical performance.

4. Key Applications and Industry Cases

Fasteners provide load transfer, vibration resistance, corrosion protection, and precise positioning. For example, a typical passenger car uses 2,000–3,000 fasteners, critical to vehicle safety and reliability.

5. Industry Trends and Market Outlook

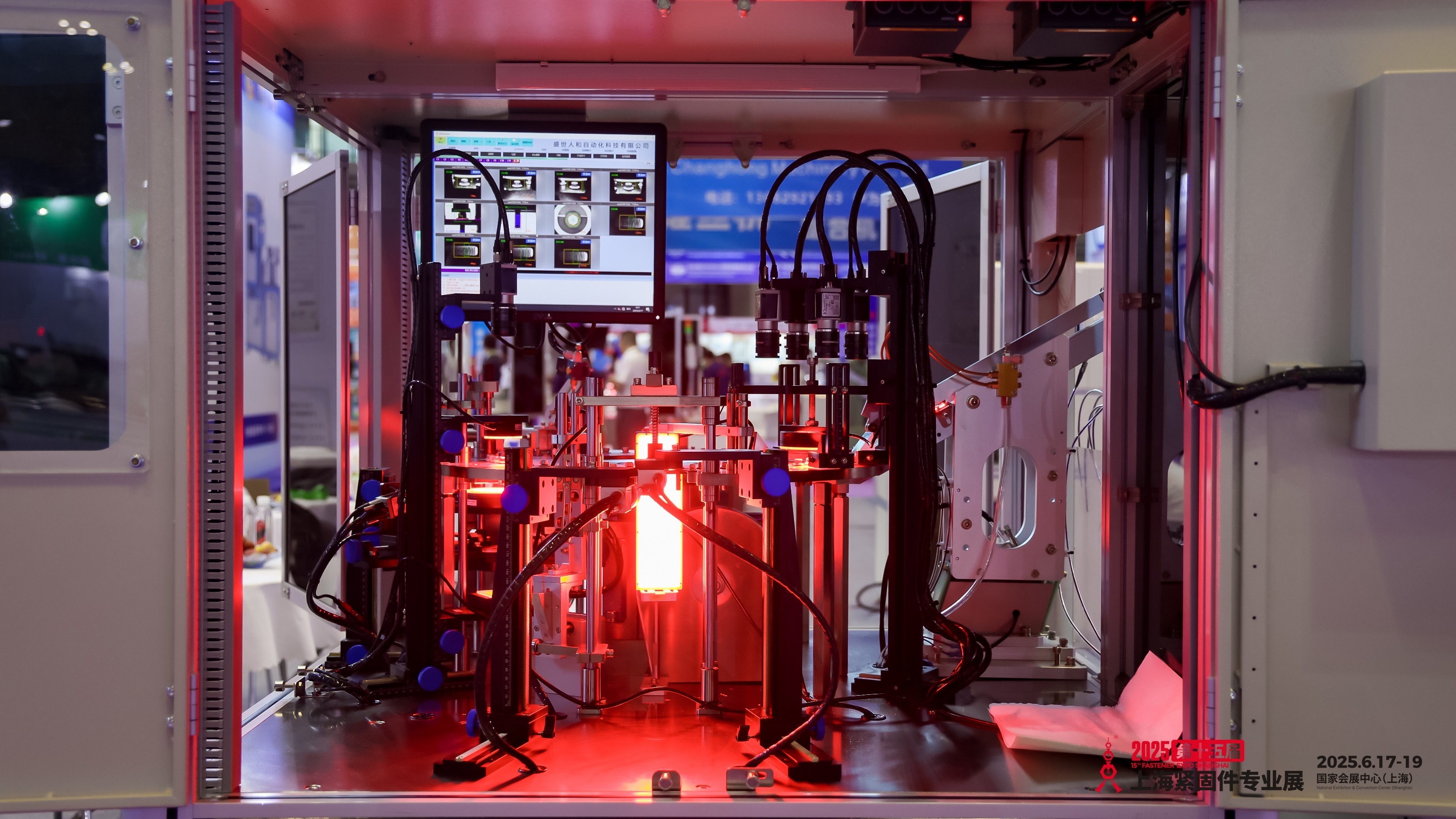

With smart manufacturing and advanced equipment demand rising, the fastener industry is moving toward material upgrades, precision machining, and intelligent assembly. The global fastener market is expected to surpass $120 billion by 2026, with China producing around 40% of global output.

Fastener Expo Shanghai 2026, as one of the world’s top three fastener expos, provides a key platform for industry exchange, showcasing standard fasteners, specialized systems, and smart assembly equipment across automotive, rail, new energy, aerospace, and industrial applications.

6. Conclusion: Small Parts, Big Impact

Though small, fasteners are the “invisible link” in industrial systems. Understanding fastener selection, materials, and manufacturing processes is essential for designers and manufacturers. The Fastener Expo Shanghai 2026 will provide comprehensive insights through product displays, technical forums, and case studies, helping the industry grasp the strategic value and future trends of fasteners.

Exhibition Info:

Fastener Expo Shanghai 2026

Date: June 24–26, 2026

Venue: National Exhibition and Convention Center (Shanghai)

Scale: 70,000㎡, 1,400+ exhibitors, 25,000+ professional visitors

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~