From Sampling to 100% Inspection: Fastener Quality Control Enters a Data-Driven Era

As the manufacturing industry moves toward higher reliability and consistency, the fastener sector is upgrading its quality management from experience-driven to data-driven approaches. In high-safety applications such as automotive, rail transit, wind power, and construction machinery, traditional sampling-based quality control can no longer ensure the stability required for large-scale production. A “full-inspection” quality system—combining laboratory testing, in-process monitoring, and third-party verification—is gradually becoming the new industry standard.

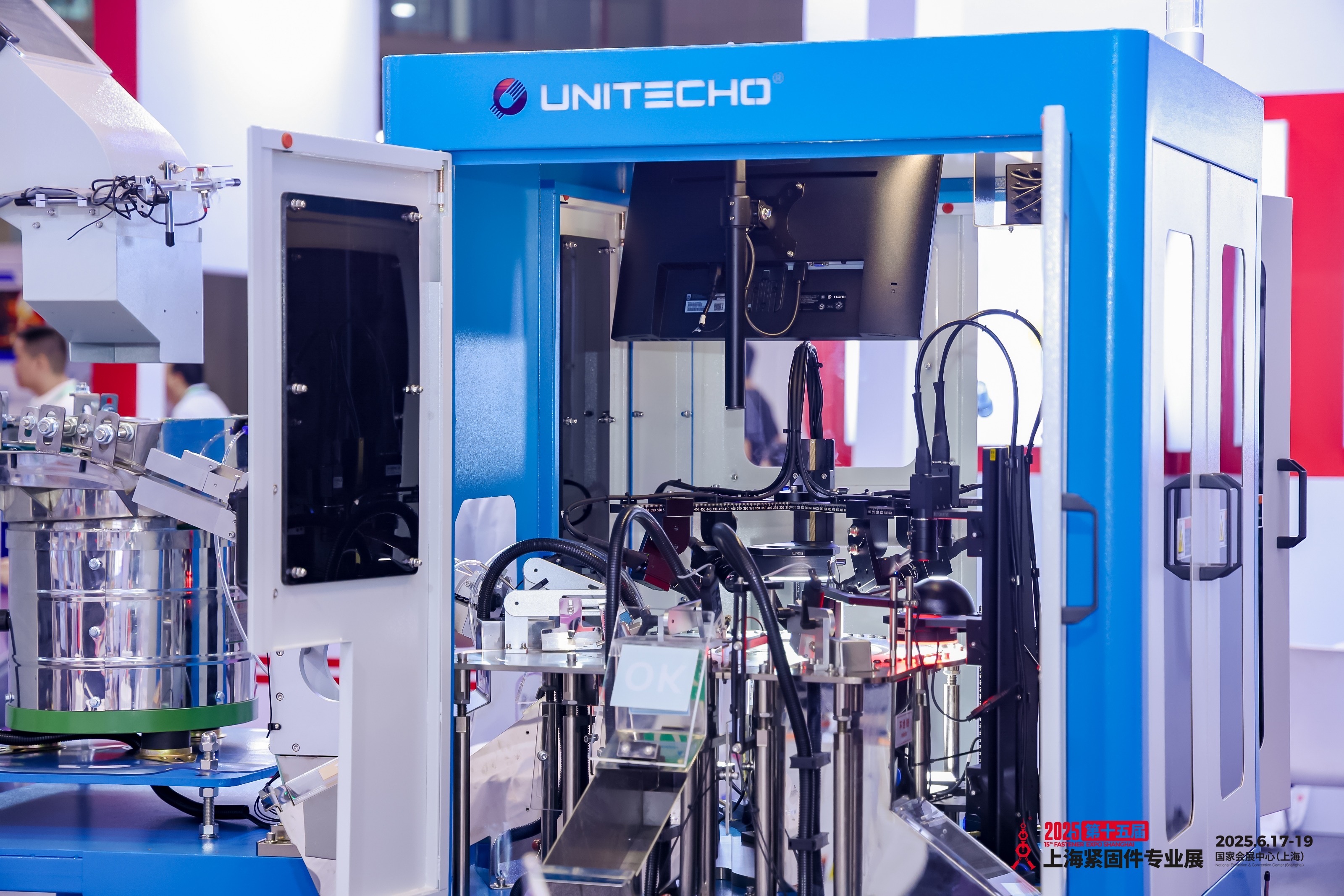

The Fastener Expo Shanghai 2026 will take place from June 24–26, 2026 at the National Exhibition and Convention Center, Shanghai. Covering 70,000 sqm, the exhibition will host 1,400+ exhibitors and 25,000+ professional visitors. The show will focus on full-process inspection equipment, laboratory capabilities, and quality management solutions, providing manufacturers and end-users with a clear view of the industry’s quality upgrade path.

Traditionally, fastener manufacturers relied on “incoming material sampling + finished product sampling.” While cost-effective for small-scale production, this approach increasingly risks missing defects as downstream customers demand batch consistency, traceability, and risk control. Especially for high-strength bolts and critical components, a single defective product can trigger system-level failures. Full-process inspection—from material performance tests and dimensional monitoring to mechanical property validation—has become essential for modern quality management.

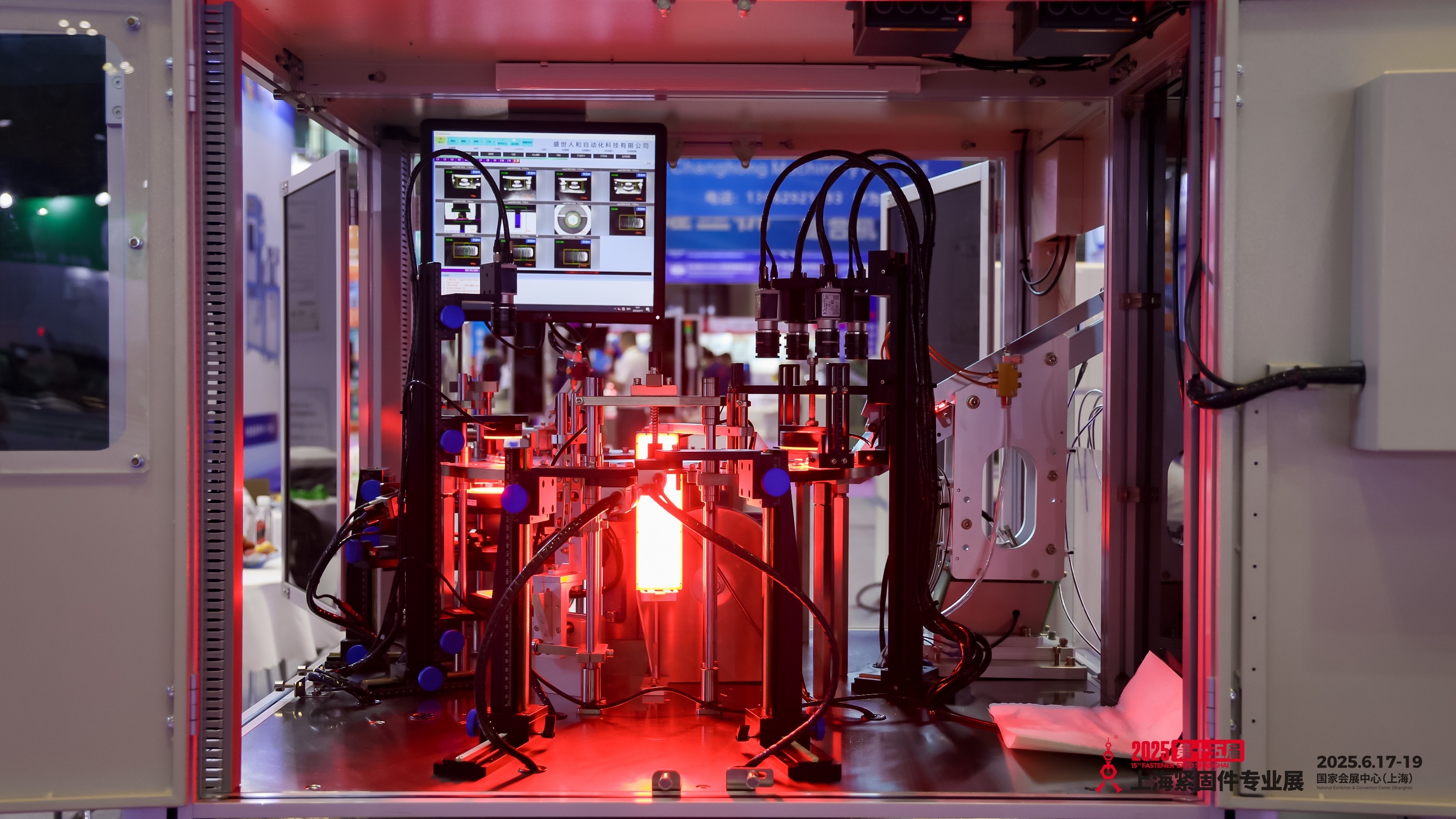

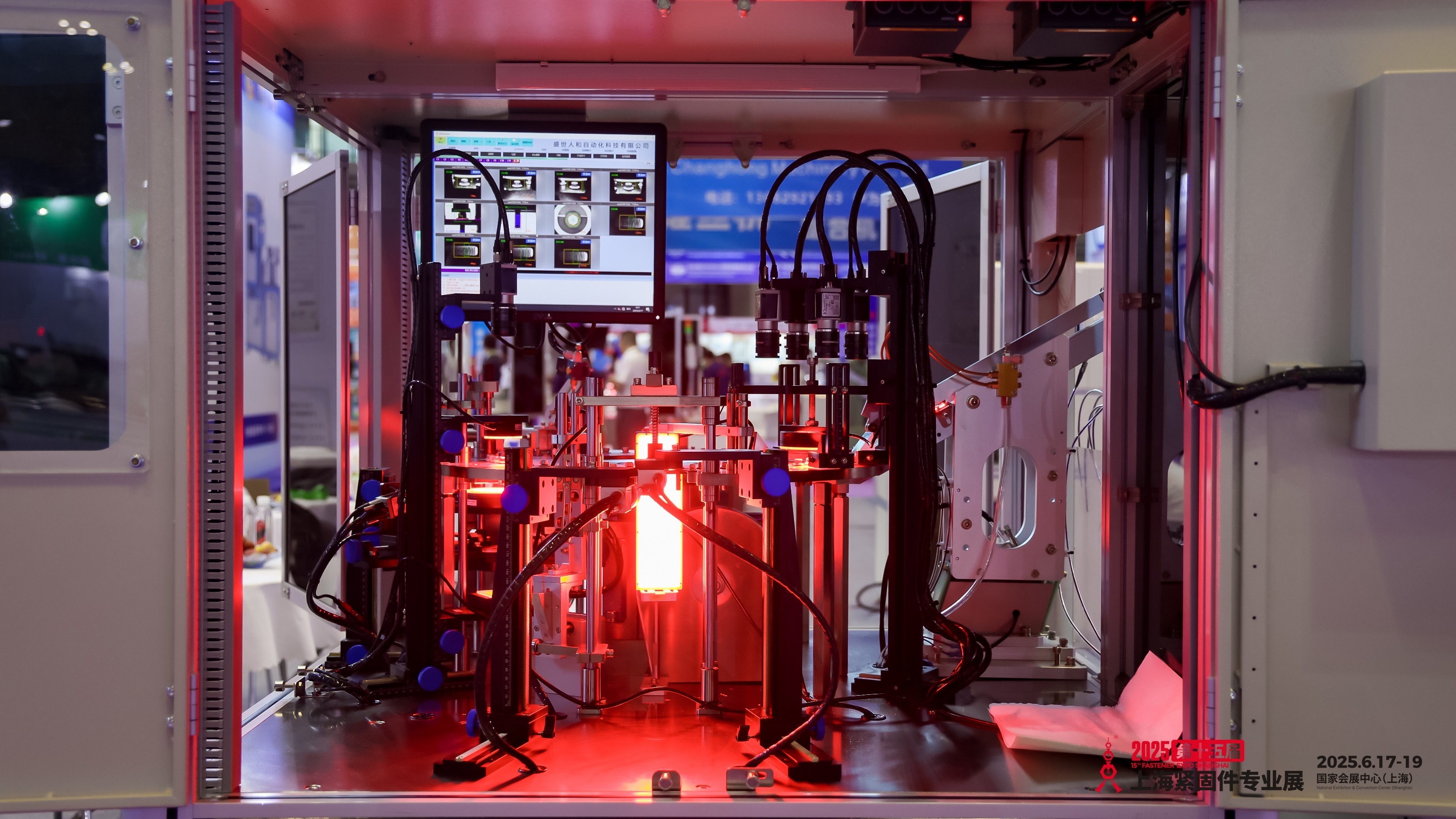

Full inspection is not merely increasing inspection frequency. It integrates metallographic analysis, chemical composition testing, and mechanical testing in laboratories with online sorting, dimensional vision inspection, and process data collection on the production floor, shifting quality control from “post-judgment” to “process control.” Companies like Zhejiang Quanyou Standard Parts Co., Ltd. have adopted systematic inspection measures to reduce variability and enhance reliability.

Improved inspection capabilities also drive the evolution of industry standards and quality awareness. Increased participation in standardized inspection systems enhances data transparency and provides reliable supply chain management. The trade show platform further amplifies these efforts. With fifteen editions of sustained growth, Fastener Expo Shanghai (FES) has become one of the “top three global fastener exhibitions,” renowned for exhibitor quality, technical content, and international buyer engagement. The 2026 edition will continue showcasing quality control solutions, inspection equipment, and industry best practices.

Transitioning from sampling to full inspection represents a systemic upgrade in cost structures, management processes, and customer relationships. Whether strengthening internal inspection capabilities or leveraging third-party services, the goal is clear: reduce uncertainty and improve delivery reliability. As fastener applications continue to expand, full-inspection quality management is becoming the industry’s new standard.

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~