High-End Fasteners in Rail Transit Enter a Competitive Phase, Domestic Substitution Window Opens

As China’s rail transit continues to expand across high-speed rail, urban rail, and conventional rail, the demand for critical components is undergoing structural upgrading. High-end fasteners, as fundamental elements of rail transit safety systems, directly affect train operation safety, maintenance costs, and overall lifecycle efficiency. With the accelerated localization of equipment, the market competition landscape for high-end fasteners is evolving, opening a window for domestic substitution.

Domestic Substitution Advancing Steadily

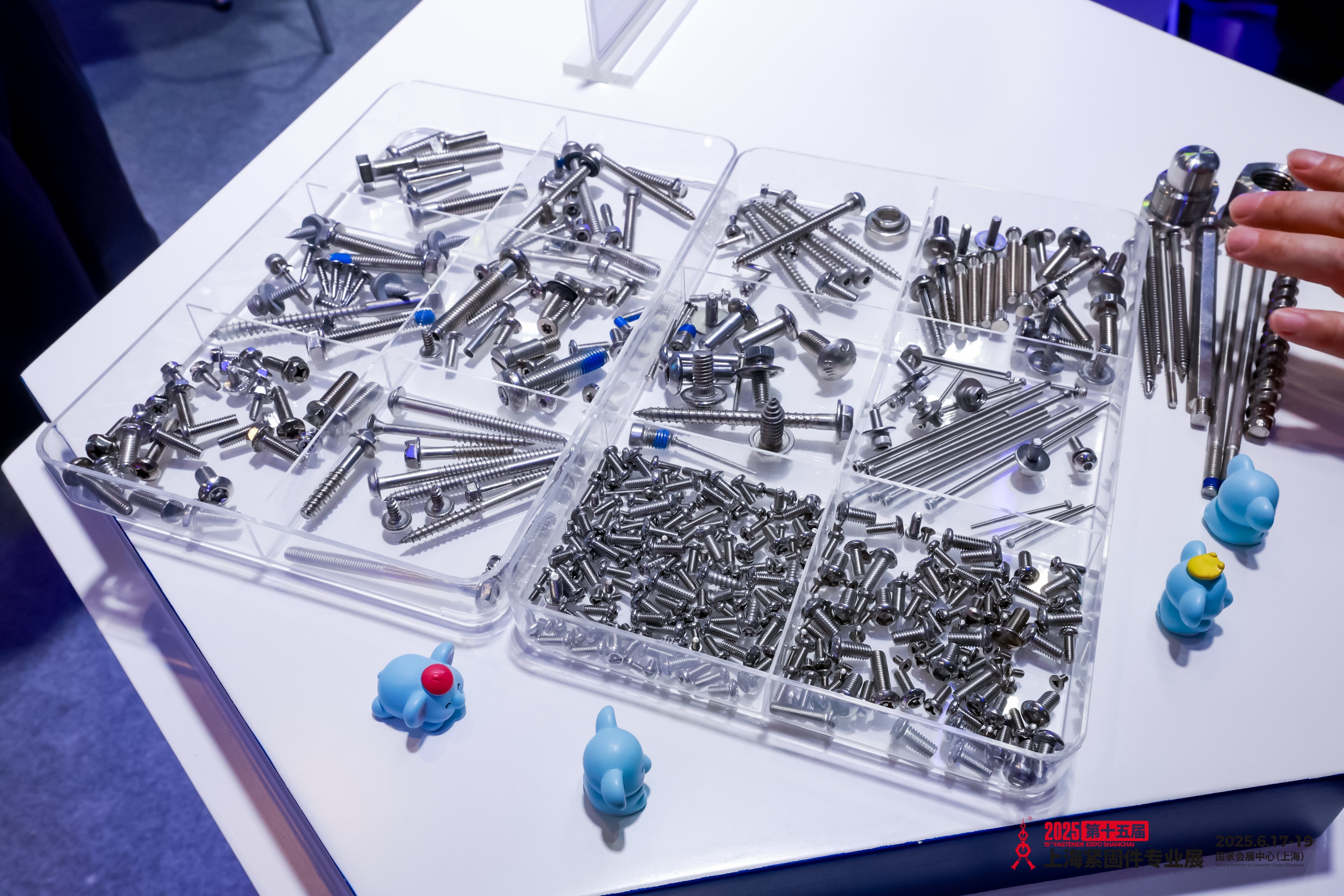

China’s rail fastener industry started later but has developed rapidly. In the early stages of high-speed rail, key components such as fastening bolts, rail clips, and vehicle connection parts relied heavily on imports due to high technical barriers in fatigue life, anti-loosening, corrosion resistance, and extreme environment adaptability. As the domestic high-speed rail system matures, local companies have strengthened R&D investment, improving the domestic content rate of rail fasteners. Notably, a number of enterprises now offer complete system supply capabilities in clip systems, structural bolts, and large rail equipment. The industry sees domestic substitution moving from isolated breakthroughs to systematic collaboration.

Performance requirements for rail fasteners are rising, shifting competition from “materials and strength” to “system capability.” Fasteners in track clip systems must withstand billions of cycles of dynamic loads; harsh environments like sand, coastal areas, and low temperatures require superior anti-corrosion and anti-loosening properties; high-strength bolts in vehicle structures must maintain preload and torque coefficient stability. Domestic companies are increasingly capable of meeting these demands, positioning them to compete with international brands in high-end markets.

Driving Factors for Domestic Substitution

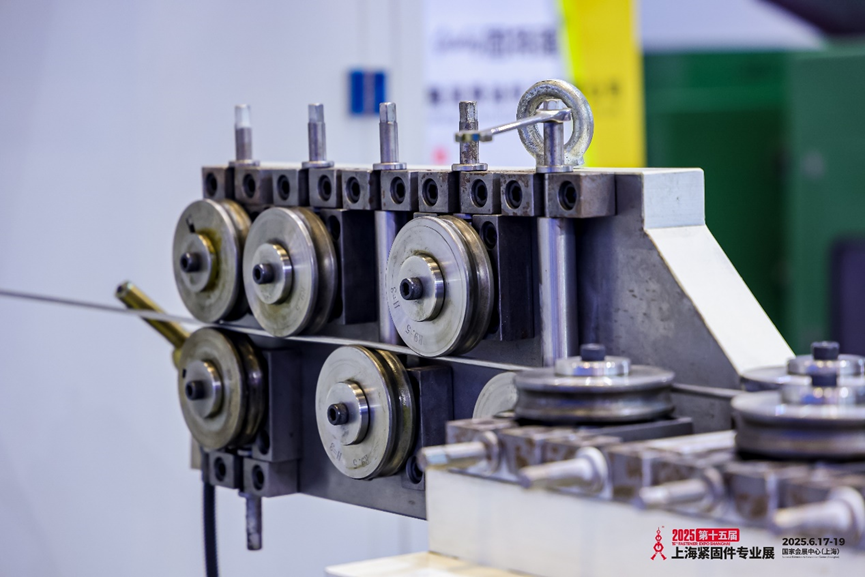

In the coming years, competition in high-end rail fasteners will intensify, with domestic substitution advancing through material upgrades, reliability improvements, and lifecycle service systems. Investment in metallurgy, heat treatment precision, and surface treatment technologies, coupled with system services, maintenance solutions, and digital monitoring capabilities, will enhance competitiveness.

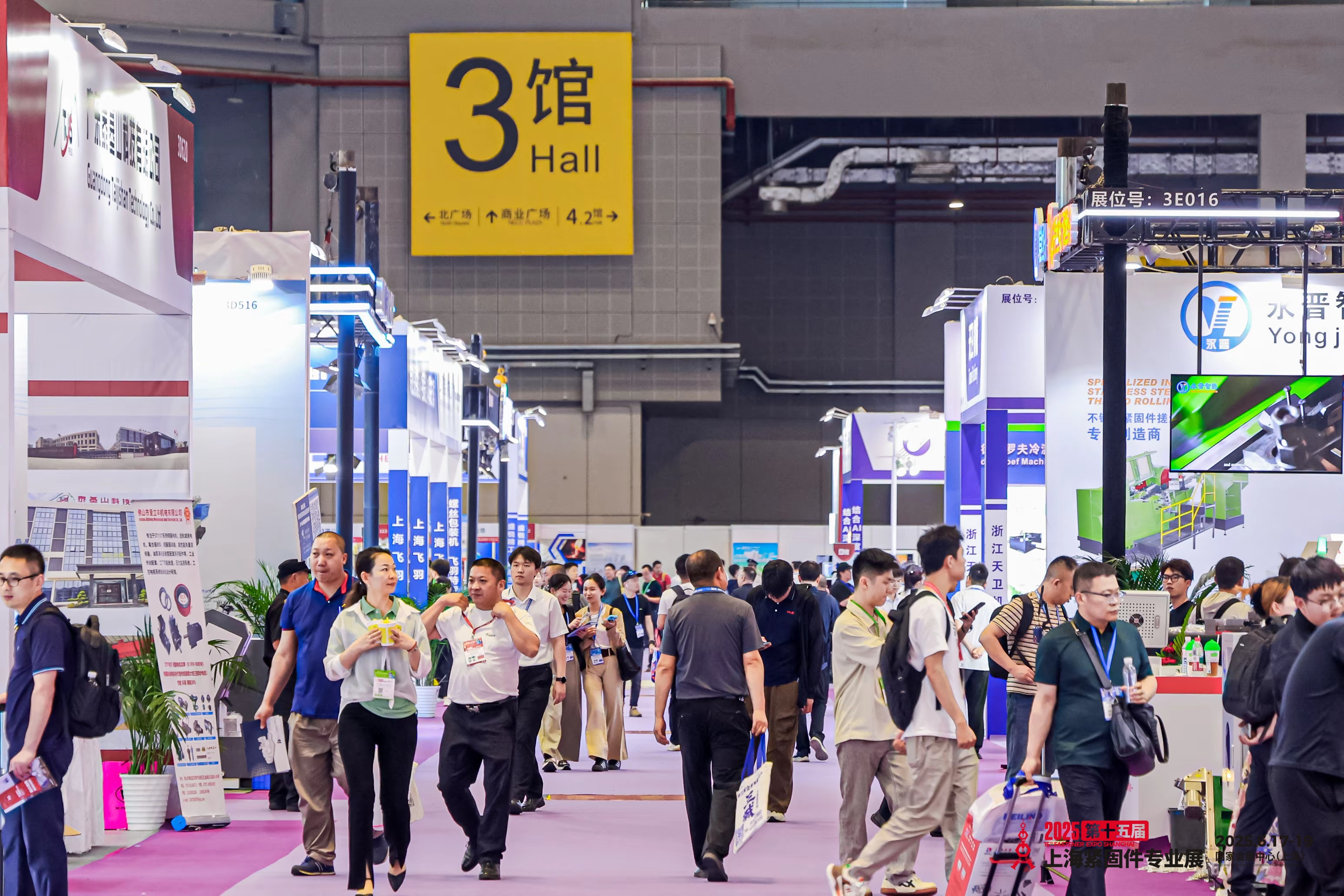

At this critical juncture for industry upgrading, communication and cooperation platforms are essential. The Fastener Expo Shanghai 2026, taking place June 24–26 at the National Exhibition and Convention Center, Shanghai, will highlight rail transit fasteners. Through forums, specialized displays, and supplier-buyer matchmaking, the expo enables direct engagement with OEMs, design units, and system integrators, promoting domestic brands in rail supply chains and showcasing advancements in material technology, reliability validation, and innovative structures.

China’s rapid rail transit development provides long-term growth opportunities for high-end fasteners. As domestic companies continue to break technical barriers, the high-end rail fastener market will become more open and competitive. FES 2026 will continue to drive this trend, providing a professional platform for industry exchange and supporting domestic brands to secure a strong foothold in high-end equipment manufacturing.

After fifteen consecutive editions, the Fastener Expo Shanghai (FES) has developed into one of the “three major global fastener trade shows.” Its exhibitors, product quality, event content, the number of domestic and international visitors, and on-site transaction volume all set industry benchmarks. In 2025, the expo further became the largest fastener exhibition in the world in terms of exhibition area.

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~