Digital Transformation and the Practical Upgrade Path of Private Fastener Factories

As manufacturing advances toward digital and intelligent production, change within the fastener industry is unfolding quietly but steadily. For China’s many private fastener factories, digitalization is no longer a matter of choice—it has become a question of where to start and how to progress without disrupting stability.

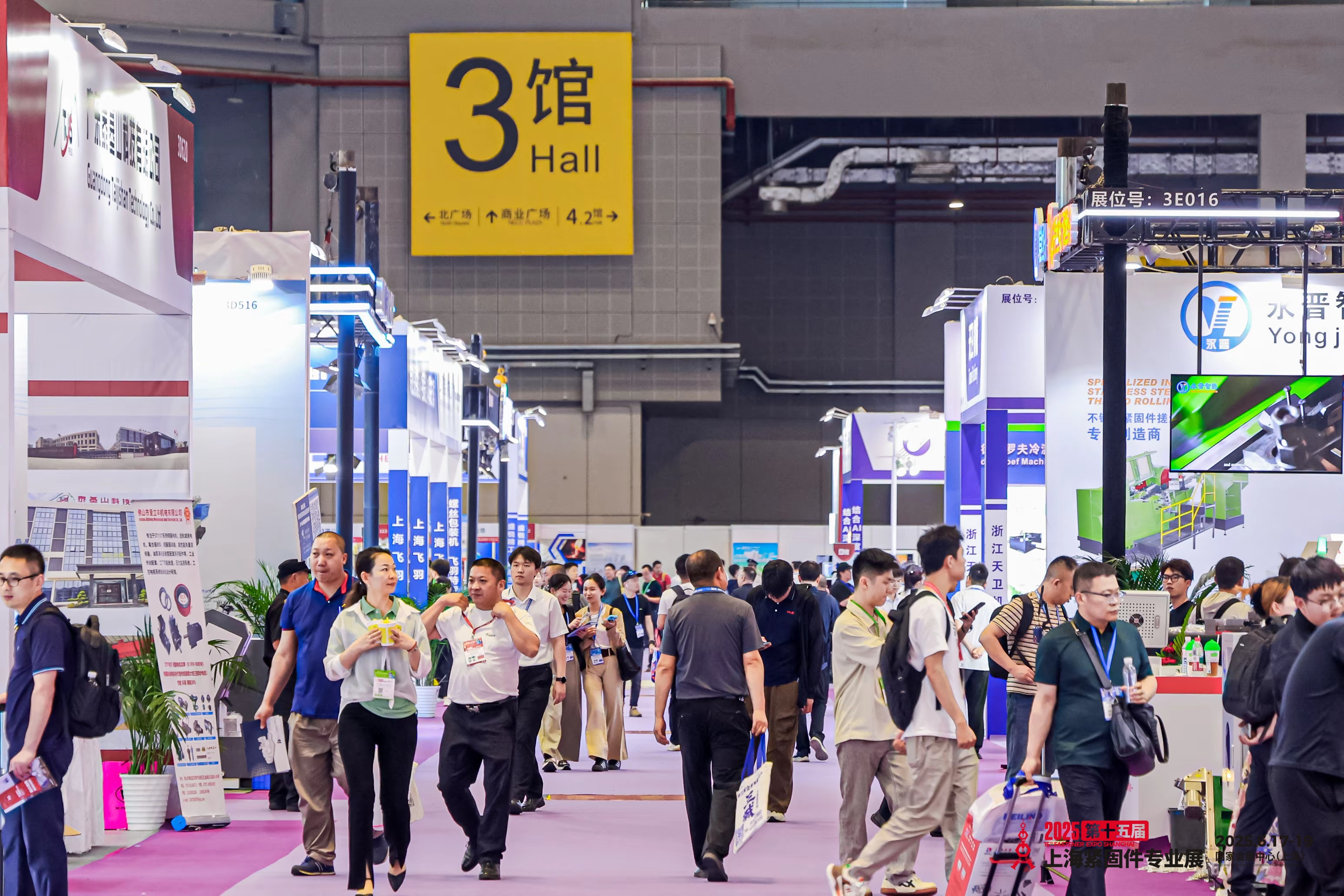

This shift will be reflected at Fastener Expo Shanghai 2026, taking place from June 24–26, 2026. Increasingly, factory owners and managers attend not only to evaluate equipment, but to explore systems, data, and management solutions that fit their operational realities.

In practice, digital transformation in private fastener factories rarely begins with large-scale overhauls. It often starts with basic information management—bringing orders, inventory, and production schedules into simple systems to improve visibility and coordination. While modest, this step lays the foundation for more structured decision-making.

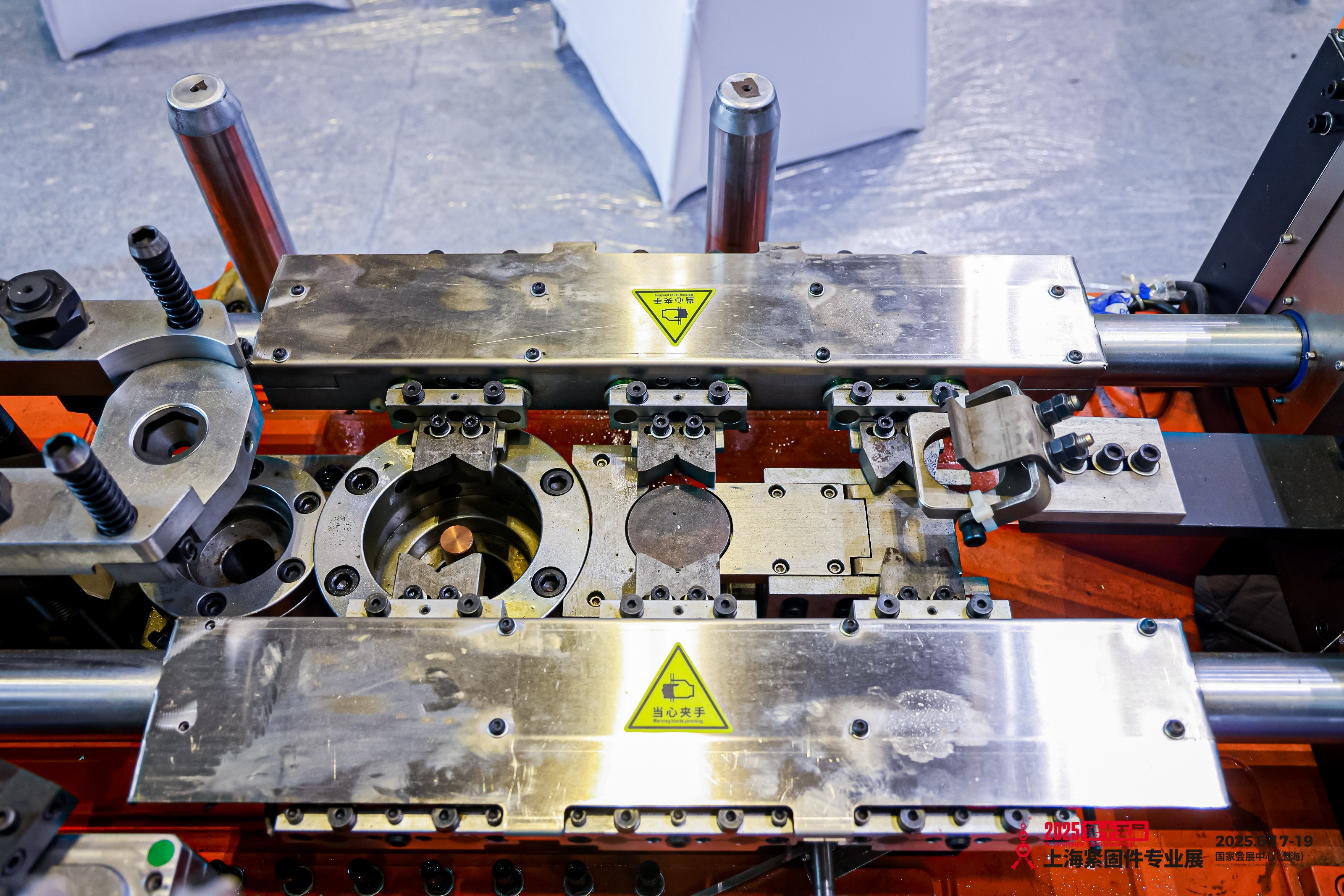

As data accumulates, digitalization gradually extends to the shop floor. Monitoring key equipment allows managers to identify bottlenecks through data rather than intuition. This transparency often becomes the most tangible and persuasive part of the transformation process.

Quality management is another area seeing clear impact. With higher demands for consistency and traceability from downstream industries, digital records and batch tracking help factories identify issues faster, reduce disputes, and meet the requirements of higher-end supply chains.

Some private enterprises have already taken practical steps—introducing unified management systems or collecting data from critical processes to support optimization and maintenance. These initiatives are typically incremental, aligned with real operational needs rather than ambitious digital blueprints.

In the long run, digitalization reshapes how private fastener factories compete. Improved delivery forecasting, cost control, and customer responsiveness turn data into a strategic asset, not just an internal tool.

Digital transformation may not be dramatic, but step by step, it is redefining the role and resilience of private fastener factories in a changing industry landscape.

After fifteen consecutive editions, the Fastener Expo Shanghai (FES) has developed into one of the “three major global fastener trade shows.” Its exhibitors, product quality, event content, the number of domestic and international visitors, and on-site transaction volume all set industry benchmarks. In 2025, the expo further became the largest fastener exhibition in the world in terms of exhibition area.

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~