Corrosion Resistance, Fatigue Performance and Hydrogen Embrittlement Control Become Key Focus Areas for Special Fasteners

As global manufacturing continues to advance toward high-strength, high-reliability applications in sectors such as offshore energy, advanced equipment, and new materials, special fasteners are gaining strategic importance across the industrial value chain. Beyond simple mechanical connections, fasteners are increasingly recognized as critical safety components that directly affect service life, reliability, and operational risk.

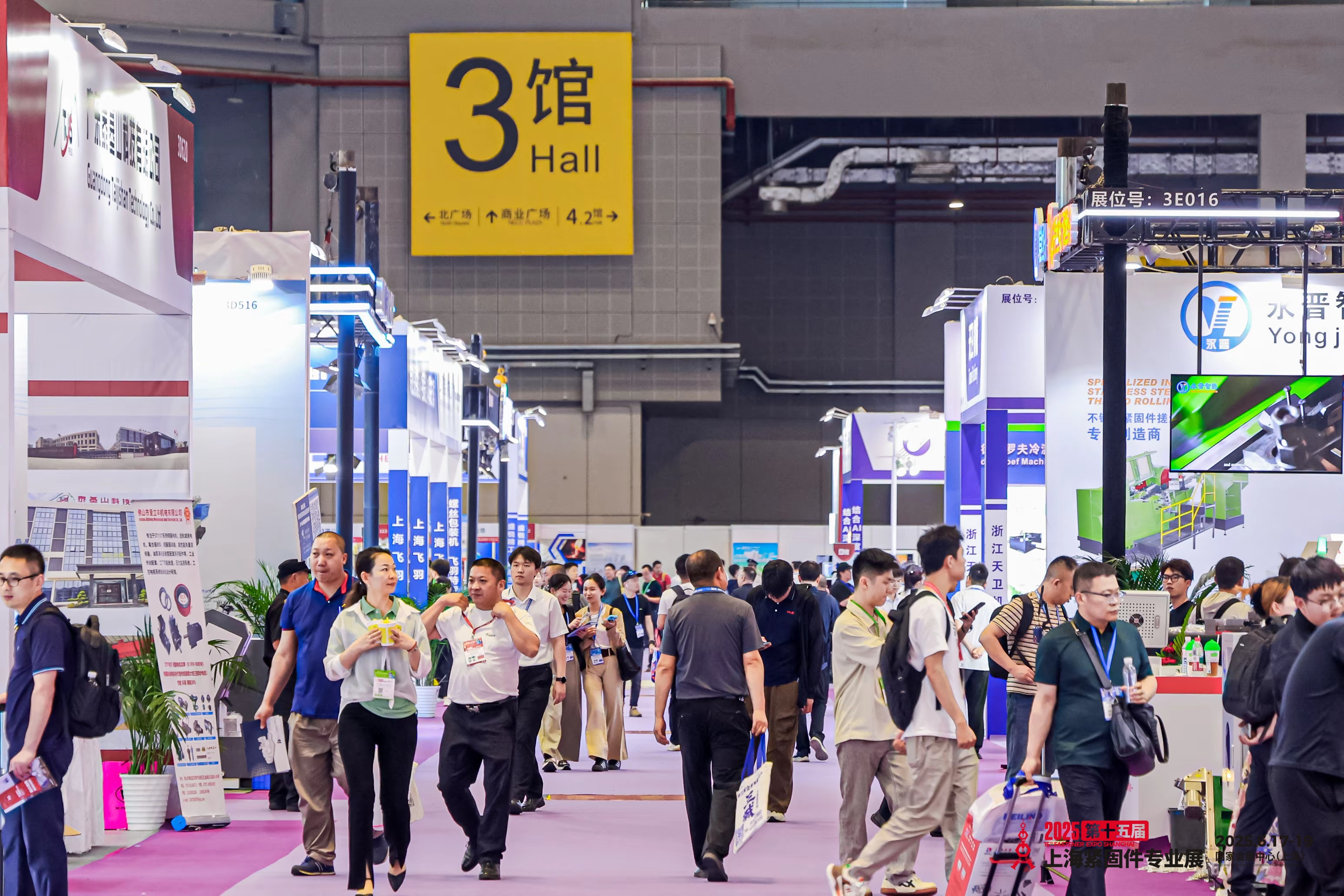

Against this backdrop, Fastener Expo Shanghai 2026, taking place on June 24–26, 2026 at the National Exhibition and Convention Center (Shanghai), will introduce a dedicated Special Fasteners Quality Control Zone. The initiative will focus on corrosion resistance certification, advanced fatigue testing systems, and hydrogen embrittlement prevention technologies, reflecting the industry’s shift toward higher quality and reliability standards.

From Nominal Strength to Long-Term Reliability

In modern high-end equipment manufacturing, fastener performance is no longer evaluated solely by material grade or tensile strength. Applications such as wind turbine flange bolts, duplex stainless steel fasteners for offshore equipment, 10.9/12.9 grade fasteners for heavy engineering structures, and battery pack connections for new energy vehicles all require comprehensive verification of corrosion resistance, fatigue durability, and service stability.

Industry experts increasingly agree that the next stage of competition will center on validated long-term reliability under real operating conditions, rather than isolated material or strength indicators.

Multi-Scenario Corrosion Validation Becomes the New Standard

Corrosion testing is evolving from reliance on neutral salt spray (NSS) toward more comprehensive and application-oriented validation systems. CASS testing, composite coatings, cathodic protection assessment, and long-term adhesion stability evaluations are now widely adopted to simulate harsh environments such as high salinity, humidity, and chloride exposure.

In offshore wind and automotive chassis applications, pitting and crevice corrosion have driven greater adoption of advanced coatings and corrosion-resistant alloys. Testing institutions are expanding their scope from test duration to failure mode analysis and coating–substrate interaction, signaling a clear shift toward standardized, real-world corrosion assessment.

Fatigue Testing Moves Toward Data-Driven Development

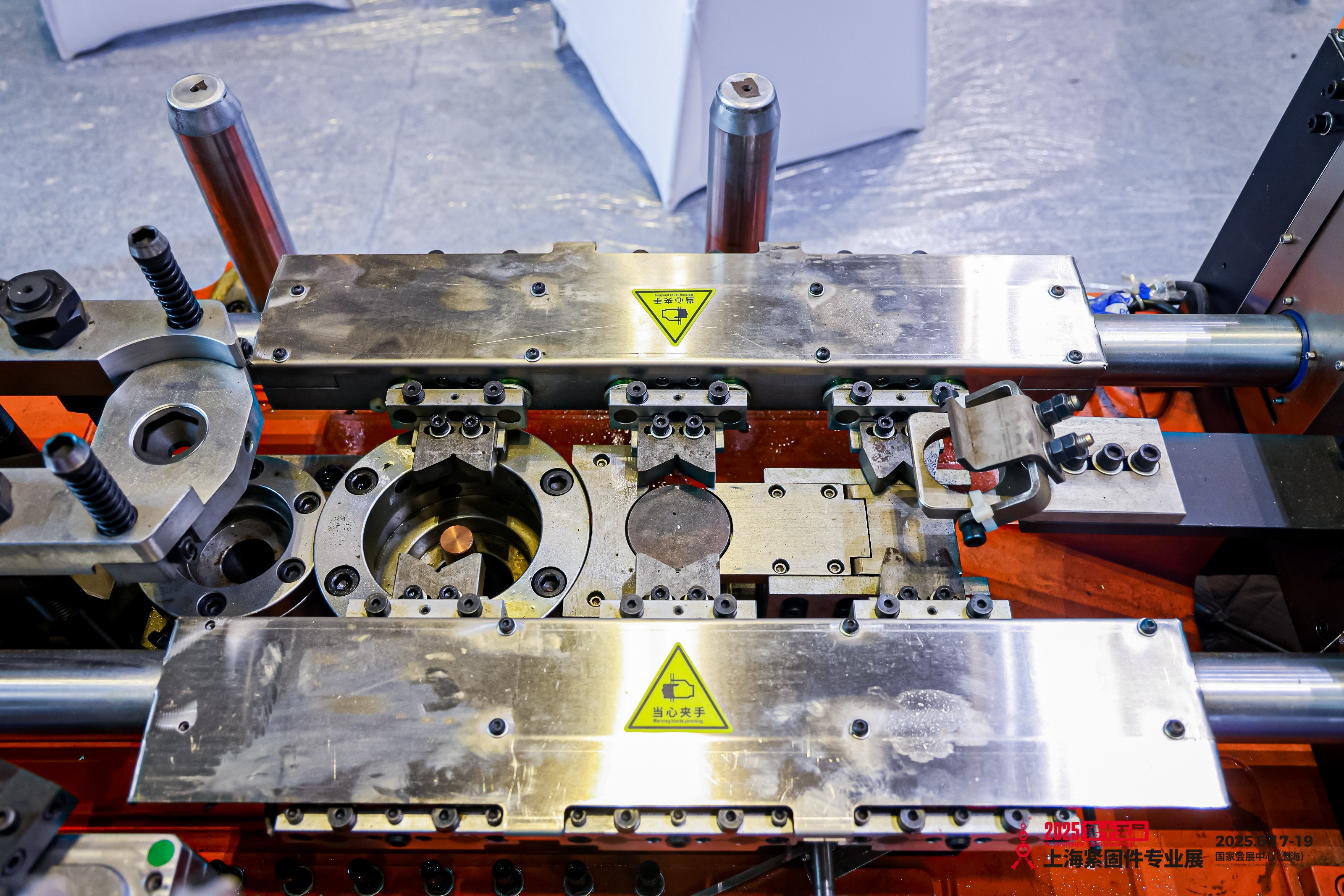

Fatigue performance evaluation is also undergoing a major transition. Under cyclic loading, vibration, and impact conditions, fastener reliability is determined less by static strength and more by crack initiation and propagation behavior.

To address this, manufacturers are increasingly investing in high-frequency fatigue testing equipment, stress-ratio cycling systems, and fatigue performance databases linked to surface treatments. In sectors such as rail transportation, petrochemical equipment, and construction machinery, fatigue testing has become as critical as strength validation itself.

Hydrogen Embrittlement Control as a Critical Quality Challenge

Hydrogen embrittlement remains one of the most challenging issues for high-strength fasteners, particularly above property class 10.9. Improper control during pickling, plating, heat treatment, or hydrogen relief processes can result in delayed fracture, sometimes occurring within 24–48 hours after installation.

As a result, the industry is strengthening its hydrogen control frameworks, including optimized surface pretreatment, vacuum dehydrogenation, delayed fracture testing, and full-process traceability. These measures are rapidly becoming standard practice in high-end fastener manufacturing.

Fastener Expo Shanghai 2026 as a Platform for Systematic Quality Advancement

The upgrading of quality systems for special fasteners is driving coordinated progress across materials suppliers, surface treatment providers, testing laboratories, and end users. Demand for duplex and super-austenitic stainless steels, low-hydrogen plating systems, and advanced coatings continues to grow.

At Fastener Expo Shanghai 2026, specialized exhibition zones, technical forums, and technology showcases will present the latest developments in corrosion resistance, fatigue testing, and hydrogen embrittlement control. The event is expected to attract 1,400+ exhibitors and over 25,000 professional visitors, creating a comprehensive platform for technical exchange and supply chain collaboration.

As the fastener industry transitions from standardized components to high-performance engineered solutions, systematic quality control and lifecycle reliability are reshaping the competitive landscape. Fastener Expo Shanghai will continue to play a vital role in supporting this transformation and advancing global fastener engineering standards.

After fifteen consecutive editions, the Fastener Expo Shanghai (FES) has developed into one of the “three major global fastener trade shows.” Its exhibitors, product quality, event content, the number of domestic and international visitors, and on-site transaction volume all set industry benchmarks. In 2025, the expo further became the largest fastener exhibition in the world in terms of exhibition area.

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~