Upgraded Fastener Performance Drives Vehicle Chassis into a New Era of Durability

As China’s automotive industry moves into a phase of high-quality development, the criteria for vehicle competitiveness are evolving. Speed and headline specifications are no longer enough. Long-term durability, structural stability, and reliability over years of operation are becoming decisive factors—bringing renewed attention to components that are rarely visible but fundamentally critical.

Among them, chassis fasteners are emerging as a key determinant of vehicle longevity.

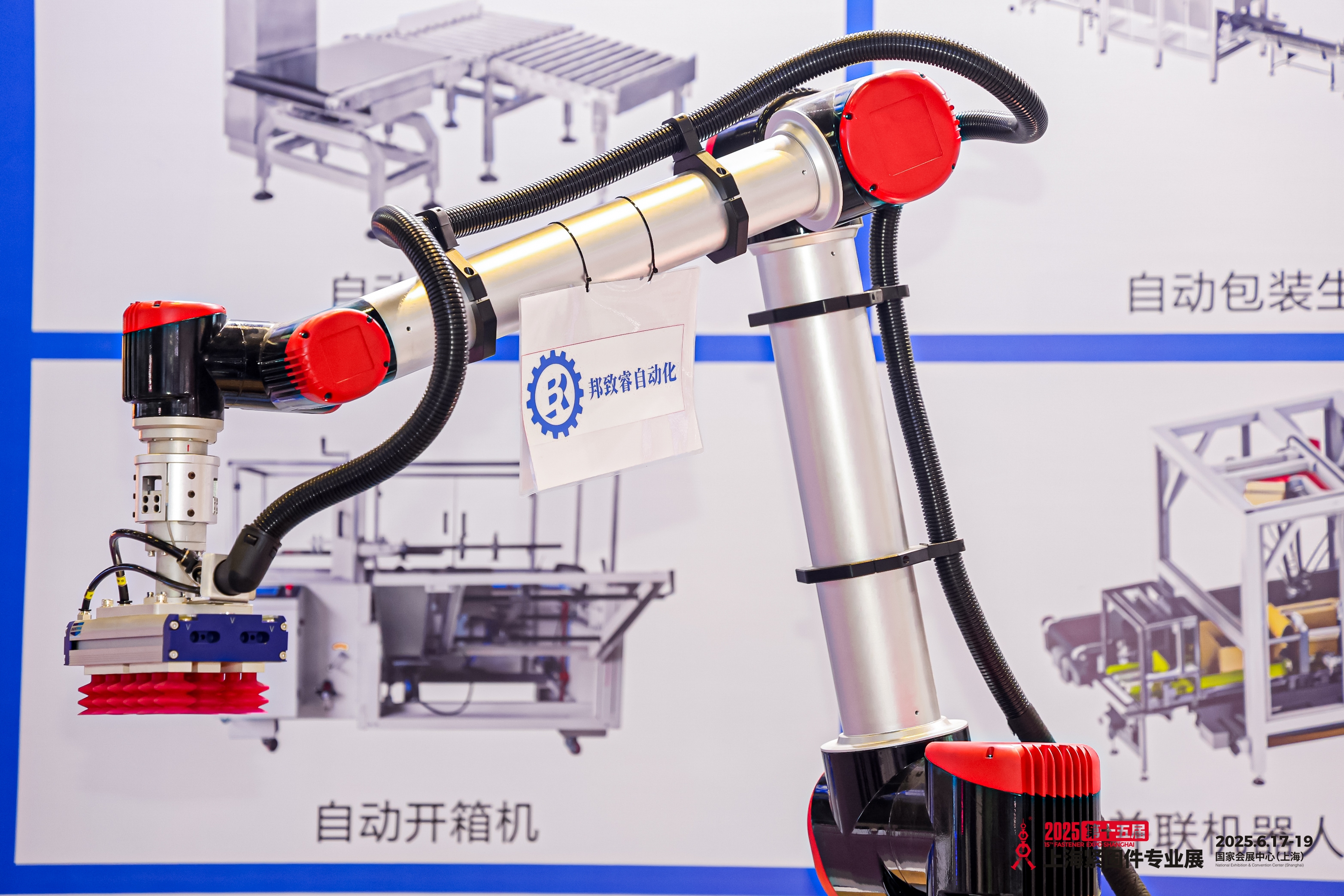

Fastener Expo Shanghai 2026, to be held on June 24–26, 2026 at the National Exhibition and Convention Center (Shanghai), will highlight chassis connection systems as a featured focus. Dedicated zones will address high-strength bolt fatigue validation, chassis connection reliability, material and heat treatment control, preload quality improvement, and in-service bolt monitoring, reflecting the industry’s shift toward durability-oriented engineering.

Industry studies consistently point to a critical reality: the long-term reliability of a vehicle is often defined by the performance of fasteners hidden beneath the chassis. Bolts used in suspension systems, steering assemblies, and subframes endure continuous vibration, cyclic loads, environmental exposure, and transient peak stresses. Their fatigue limits directly influence whether a vehicle can maintain safety and stability throughout a decade or more of service.

Under proper preload conditions, typical grade 10.9 chassis bolts can achieve fatigue limits in the range of 380–420 MPa. However, insufficient preload or assembly deviations can reduce this value by more than 20%, significantly shortening service life. The difference may appear marginal, but its impact on durability is substantial.

Fatigue performance is critical because chassis fasteners are subject to complex, combined loading conditions rather than static forces. While material strength provides the foundation, factors such as thread geometry, stress concentration control, surface treatment stability, preload retention, and accurate load spectrum assessment ultimately determine service life. Test data show that even high-grade fasteners experience drastically reduced fatigue life under low-preload conditions—underscoring the importance of system-level design rather than isolated material upgrades.

In response, Chinese fastener manufacturers are increasingly engaging in chassis-level durability research. Companies such as Shanghai Yixuan Automotive Standard Parts Co., Ltd. and Zhejiang Shanbao Automotive Components Co., Ltd. have developed more application-oriented fatigue testing and process optimization strategies.

These practices reinforce a growing consensus: chassis fasteners are no longer simple standard components, but safety-critical parts requiring integrated development across materials, structure, heat treatment, surface engineering, and assembly control.

At the same time, the industry recognizes that manufacturing improvements alone are not sufficient. Road-load studies show that preload history and real-world operating conditions significantly affect fatigue life. When preload is accurately controlled and assembly processes are stable, measured service life closely matches theoretical predictions. Conversely, even premium fasteners may fail prematurely without proper system coordination.

As a result, OEM requirements for chassis fasteners are evolving toward comprehensive traceability, standardized validation procedures, and lifecycle fatigue assessment. Fastener Expo Shanghai 2026 will provide a practical platform for this transition, bringing together fastener manufacturers, vehicle engineers, and supply-chain partners to exchange verified solutions and technical insights.

Industry experts note that China’s automotive competitiveness is shifting from speed and scale to reliability and durability. Although small in size, chassis fasteners directly reflect the maturity of foundational connection technologies. With sustained investment in fatigue research, process control, and validation systems, domestic chassis fasteners are rapidly closing the gap with global leaders.

A single bolt may go unnoticed, but it often determines whether a vehicle retains its integrity after hundreds of thousands of kilometers. As attention continues to move toward fatigue resistance, connection reliability, and assembly consistency, China’s automotive industry is entering a genuinely high-durability era—built from the ground up.

After fifteen consecutive editions, the Fastener Expo Shanghai (FES) has developed into one of the “three major global fastener trade shows.” Its exhibitors, product quality, event content, the number of domestic and international visitors, and on-site transaction volume all set industry benchmarks. In 2025, the expo further became the largest fastener exhibition in the world in terms of exhibition area.

Official Website: www.fastenerexpo.cn/en

Media Contact: Goblic Hu

Email: goblic.hu@ebseek.com

Phone: +86 138 1631 0340

Please first Loginlater ~