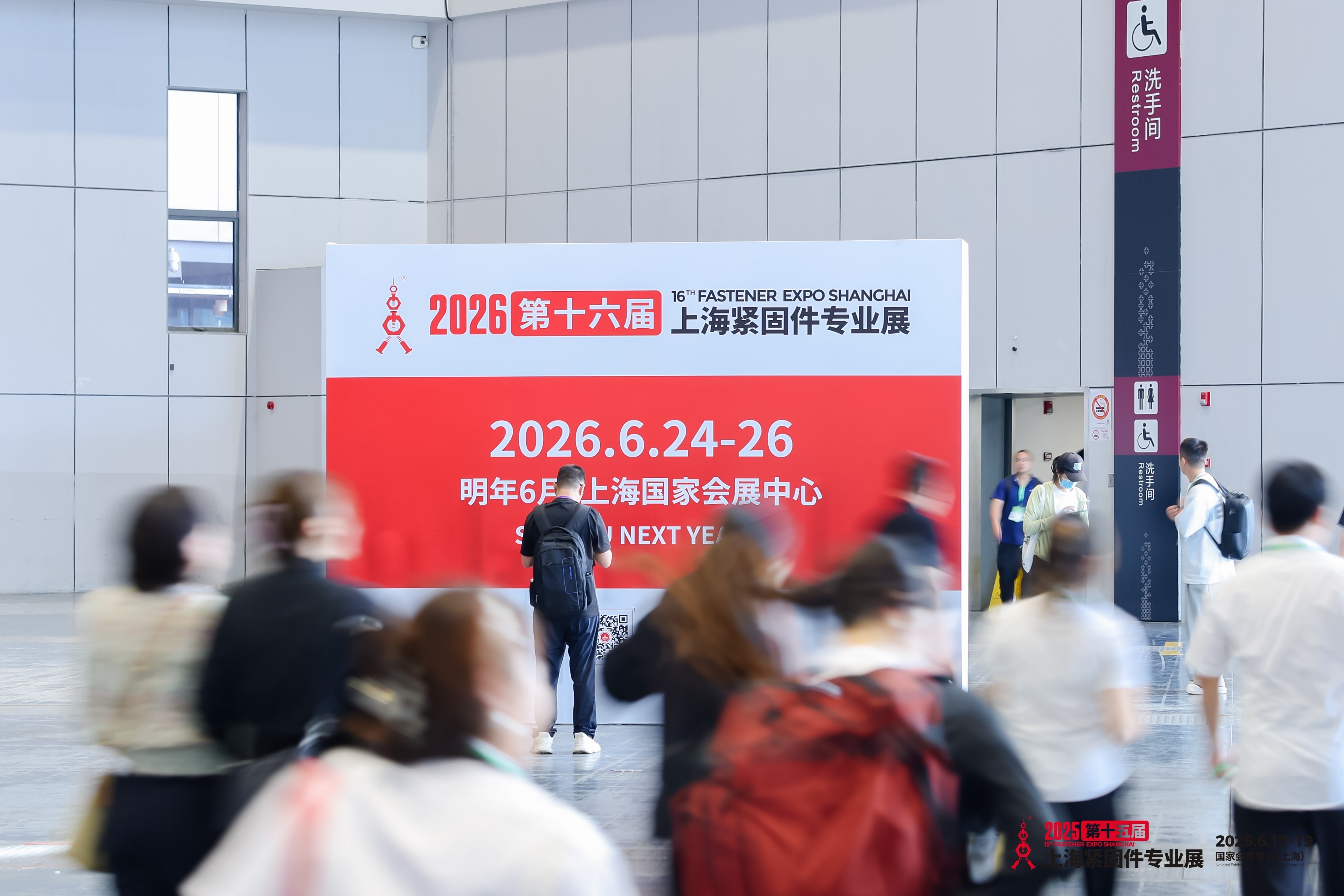

Exhibitor Spotlight: Cold Heading Machine Manufacturers Unveil Latest Technologies at Fastener Expo Shanghai to Boost Production Efficiency

Understanding Cold Heading Machines

A cold heading machine is a specialized piece of equipment used to manufacture cold-formed fasteners. It is widely applied across industries such as automotive, machinery, aerospace, and construction. The machine operates by cold-forming metal wire through molds and applied pressure, producing fasteners like bolts, nuts, and washers in various specifications. Leveraging an efficient cold heading process, these machines enable high-volume, high-precision production at lower temperatures, significantly boosting productivity, reducing energy consumption, and ensuring consistent product quality.

In the fastener industry, cold heading machines not only enhance automation in manufacturing but also ensure the mechanical strength, dimensional accuracy, and surface finish of fasteners. Compared to traditional hot forming methods, cold heading effectively reduces material waste and improves the utilization of metal resources. This makes the technology especially critical in sectors like automotive and machinery, where fastener performance and reliability are paramount.

Cold Heading Machine Exhibitor Highlights

At this June’s Fastener Expo Shanghai, numerous cold heading machine manufacturers will showcase their latest technologies and high-efficiency equipment. They will present cutting-edge automated production processes and intelligent solutions that are driving the fastener industry toward greater precision and higher productivity.

Ningbo Haixing Machinery Manufacturing Co.,Ltd.

Booth: 3A002

Ningbo Haixing Machinery Manufacturing Co., Ltd. is located in the National Hi-Tech Industrial Development Zone of Ningbo, Zhejiang Province. Founded in 1999, it is a national high-tech enterprise specializing in the research, development, and production of multi-station high-speed precision cold heading machines.

The company currently operates over 70,000 square meters of international-standard factory space and is equipped with a large number of CNC machining centers and advanced processing equipment, providing strong support for the precision manufacturing of various cold heading machine components.

Haixing-brand cold heading machines fully incorporate advanced design concepts from contemporary Japanese and Taiwanese models. They are equipped with world-class electrical, pneumatic, bearing, and control systems, ensuring reliable performance and long-term durability.

Adhering to the principle of "building the brand before expanding production," Haixing implements comprehensive quality control throughout every stage of the process, with meticulous checks and fine-tuned adjustments to deliver top-quality products and services. Over the past decade, Haixing’s products have been widely recognized by many leading domestic fastener manufacturers, contributing significantly to the technological upgrading of the fastener industry.

Corinille Machinery Equipment Co., Ltd.

Booth: 3A302

Corinille Machinery Equipment Co., Ltd. is a subsidiary of Hebei Dingrun Intelligent Manufacturing Equipment, located in the scenic and historically rich city of Wu'an—renowned for its ancient smelting heritage. Established in 2020, the company has steadily accumulated technical expertise and operational strength over the past few years, positioning itself for robust growth.

The company spans an area of over 320 mu (approximately 213,000 square meters), with a total investment of 540 million RMB. It boasts 100,000 square meters of modern workshop facilities and a 10,000-square-meter R&D and administrative building. As a technology-driven mechanical equipment manufacturer, Corinille integrates research & development, production, sales, and after-sales service. It employs dozens of experienced technical engineers and has developed advanced manufacturing processes, a complete range of product lines, and fully equipped production facilities. The company maintains a rigorous commitment to quality, achieving a 99.99% pass rate for full-machine inspections—earning the trust and praise of customers both at home and abroad.

Corinille currently has over 200 employees, structured into five major departments: Machinery Production, Quality Assurance, R&D, Sales, and Administration. Each department collaborates closely to ensure efficient and high-quality operations.

Upholding the principles of excellence and customer-first service, Corinille is committed to continuous improvement and innovation. The company follows the philosophy of "survival through quality, development through credibility."

Core Products:

Corinille specializes in the manufacturing of cold forging forming machines for shaft-type parts, including: 3-die 3-blow, 4-die 4-blow, 5-die 5-blow, 6-die 6-blow up to 9-die 9-blow models.

The company also provides thread rolling machines, tapping machines, and other automated auxiliary equipment. These machines are widely used in industries such as aerospace, marine, automotive, motorcycles, electric vehicles, and mechanical components, and are capable of producing a variety of fasteners and custom non-standard shaped parts. Corinille also offers customized forming machines and professional technical support tailored to customer requirements.

The Corinille-brand cold heading machines incorporate advanced machine design concepts from Japan and Taiwan, and are equipped with globally recognized electrical, pneumatic, bearing, and control systems to ensure reliable performance and long service life. The company brings together specialized engineers and a professional team that handles everything from design and development to precision parts machining and sophisticated machine assembly. Corinille machines are well-regarded for their high precision, low noise, high efficiency, and compact footprint, and have earned widespread recognition across the industry.

Corinille’s service network spans across the globe, including countries such as Sweden, Turkey, Greece, India, Russia, Mongolia, Thailand, Vietnam, Pakistan, and others. Since its establishment, the company has adhered to the principle of "quality first, integrity-based", delivering timely and professional after-sales service to support every Corinille machine in operation.

Wenzhou Boyu Machinery Co., Ltd.

Booth: 3D302

Wenzhou Boyu Machinery Co., Ltd., established in 2006, is located in the Wenzhou Airport New District. The company operates two production and processing bases, covering a total area of 25,988 square meters with a building area of 35,000 square meters. It is a specialized manufacturer engaged in the R&D, production, and sales of fully automatic high-speed cold heading machines—dedicated equipment for metal stamping and forming.

The company's main products include conventional fully automatic high-speed cold heading machines and multi-station fully automatic high-speed cold heading machines. These products are widely used by fastener enterprises across China and are actively exported to international markets. Boyu's product range, sales volume, and product quality are all among the top in the industry, earning the company an excellent reputation.

Boyu Machinery has passed the ISO 9001 quality management system certification and the EU 2006/42/EC Machinery Directive certification. It has obtained multiple utility model patents. Through years of development, the company has built strong technical capabilities, advanced manufacturing processes, high-precision equipment, comprehensive testing methods, and strict quality control systems. It possesses integrated capabilities in product development, process design, mechanical processing, quality assurance, and after-sales service.

The company has been recognized with numerous honors, including:

- National High-Tech Enterprise

- Zhejiang Provincial "Specialized, Refined, and Innovative" Enterprise

- Zhejiang High-Growth Technology-Based Enterprise

- Zhejiang Technology-Based Enterprise

- Wenzhou "Specialized, Refined, and Innovative" Enterprise

- Wenzhou Technology-Based Enterprise

- Wenzhou High-Growth Enterprise

- Wenzhou Credit Management Demonstration Enterprise

Adhering to the philosophy of "Technology as the driver, Quality as the foundation, and Integrity toward customers," Boyu is committed to delivering excellent quality and high-performance products that have won unanimous praise from users at home and abroad. The company warmly welcomes new and existing customers from around the world to visit, cooperate, and grow together.

Hubei Tengfeng Machinery Technology Co. Ltd.

Booth: 3A102

Hubei Tengfeng Machinery Technology Co., Ltd. is a well-known enterprise that integrates research & development, manufacturing, and sales of fastener machinery equipment. The company adopts advanced scientific management practices and production processes, utilizing high-precision machining tools and equipment. It also boasts a team of experienced senior technical professionals in the industry.

With over 20 years of expertise in manufacturing machinery such as cold heading machines, thread rolling machines, open-die cold heading machines, nut forming machines, and parts forming machines, the company has built a strong reputation. Its products are exported to more than 30 countries worldwide and have earned high praise from both domestic and international customers.

Guided by the principles of innovation, cooperation, and mutual success, the company is committed to developing cutting-edge, practical, durable, and high-quality products. Hubei Tengfeng has also established a comprehensive after-sales service system to ensure that customers at home and abroad can purchase and use its equipment with complete confidence.

Shanghai Jiyou Neide Strove Precision Machinery Co., Ltd.

Booth: 3E002

Shanghai Jiyou Neide Strove Precision Machinery Co., Ltd. is the Chinese manufacturing facility of Neide Strove cold heading machines and, together with the Belgian machine factory, forms the special machine tool division under Shanghai Jiyou. The company is committed to producing high-end metal forming machinery and serving the global metal forming industry.

Neide Strove Machinery Company of Belgium is a world-leading manufacturer specializing in multi-station cold heading forming machines. With over 60 years of accumulated technology and experience, it has earned a global reputation for its outstanding machine performance and exceptionally long service life.

In terms of technological innovation, Neide Strove launched the world’s first full-servo direct-drive CNC cold heading machine in 2016, setting a new direction for R&D in the cold heading machinery industry.

In 2014, Neide Strove Machinery Company of Belgium, along with the Royal Netherlands Neide Strove Group, was fully acquired by Shanghai Jiyou, becoming a European enterprise wholly owned by Chinese capital.

In early 2022, the localization project of Neide Strove cold heading machines received official approval from Shanghai Electric Group (parent company of Shanghai Jiyou). The first phase of the domestic manufacturing plant officially began operations in November 2022.

Jiyou Neide Precision Machinery directly adopted Neide Strove’s best-selling Nedform series as its technical foundation. Its localization strategy follows the business philosophy of "high standards, strict requirements, and practical implementation," with the aspiration of making high-end cold heading equipment proudly made in China.

ShangHai YiMing Mechanical Equipment Co., Ltd.

Booth: 3D502

ShangHai YiMing Mechanical Equipment Co., Ltd. is located in the beautiful and prosperous city of Taicang. The company was initially established in Jiading, Shanghai in 2004 and relocated to Taicang, Suzhou in 2016. Geographically, it enjoys a prime location in the Yangtze River Delta economic demonstration zone, facing Chongming Island across the river to the east, and bordering Shanghai’s Baoshan and Jiading districts to the south. With excellent transport infrastructure and close proximity to multiple expressways, the company benefits from outstanding accessibility and logistics support.

The founder, Mr. Zhang Xuecai, formerly served as Technical Director of the Italian company SIBI Machinery's Shanghai branch. With many years of deep expertise in rivet machines and cold heading forming machines, he possesses rich experience in R&D and design across a wide range of machine models. Building upon the strengths of Italian SIBI Machinery, the company has continued to innovate and improve its technology.

YiMing has passed ISO 9001:2016 Quality Management System certification and CE safety certification, and holds multiple invention patents. With an exceptional R&D and manufacturing team, the company is dedicated to meticulous craftsmanship in every piece of cold heading and forming equipment, maintaining cooperation with numerous well-known domestic and international enterprises.

The company is equipped with advanced quality control and inspection processes. It specializes in manufacturing various models of rivet machines, as well as multi-station automatic high-speed cold heading machines such as 2-die 2-blow, 3-die 3-blow, 4-die 4-blow, 5-die 5-blow, 6-die 6-blow, and 7-die 7-blow configurations, along with warm forging machines. These machines are particularly focused on aerospace and military applications, capable of processing titanium alloys and high-nickel alloys, and all products meet international standards.

With innovative technical talent and advanced machining equipment, every machine produced is guaranteed for quality—featuring high precision, strong stability, fast production speeds, reasonable structure, and excellent cost-performance ratio. The equipment is widely used across automotive parts, military, and aerospace sectors.

Adhering to the philosophy of “survival through quality and development through service,” the company continuously innovates while ensuring stable product quality and improving after-sales service, removing customer concerns. YiMing sincerely looks forward to working hand in hand with new and long-term clients from around the world to create a brighter future together.

Zhejiang Jinggu Machinery Manufacture Co., Ltd.

Booth: 3A602

Zhejiang Jinggu Machinery Manufacture Co., Ltd. is located at No. 1 Shuzhuang Industrial Park, Chuanliao Town, Qingtian County, Zhejiang Province. Covering a land area of 22,000 square meters with a building area of 25,000 square meters, the company has been specializing in nut cold heading machines for over 20 years, providing customers with high-quality management and R&D capabilities.

Jinggu’s main products include multi-station bearing-type nut cold heading machines and extended copper sleeve-type part forming machines. Models range from 08B to 50B, with 6 to 8 working stations, and support customized features such as servo feeding and forging force monitoring.

The company is well-equipped with large machining centers, CNC lathes, and a metalworking workshop with efficient production lines. It operates under a MES (Manufacturing Execution System) and is backed by a strict quality inspection team.

With a dedicated R&D team continuously improving equipment and breaking technical barriers, Jinggu holds numerous utility patents and has independently developed its own intelligent control systems. The company is ISO9001 and CE certified, and its products are exported globally, serving industries such as standard fasteners, automotive and motorcycle parts, and aerospace. Its clientele includes leading fastener companies both in China and abroad.

Guided by the philosophy of "Crafting excellence, fastening with strength, quality first, customer foremost," Zhejiang Jinggu is committed to increasing R&D investment, expanding global markets, and working with partners worldwide to shape the future of intelligent manufacturing.

Huangshan Shengrui Seiko Machinery Co., Ltd.

Booth: 3A610

Huangshan Shengrui Seiko Machinery Co., Ltd., established in 2002, has made continuous progress over the past decade through scientific management and a strong focus on talent development. By cultivating a team of highly skilled, technically proficient, and socially responsible professionals, the company has consistently driven innovation in its product offerings.

The company has invested nearly 100 million RMB in acquiring over 20 high-end CNC machining centers from renowned brands such as Yamazaki Mazak and Okuma. It also utilizes Hexagon coordinate measuring instruments to ensure the high-speed and high-precision manufacturing of cold heading machine components. All materials and electrical control components are sourced from internationally recognized brands to ensure stable and reliable product quality.

Shengrui’s latest series of products have reached an internationally advanced level and are exported to over 20 countries and regions, including Sweden, Turkey, Greece, India, and Thailand.

Pingyang Tianwei Machinery Co., Ltd.

Booth: 3E008

Established in 1986, Pingyang Tianwei Machinery Co., Ltd. specializes in the production of bolt cold heading machines for over 30 years. The company is located in the Binhai Industrial Park of the Wenzhou Economic and Technological Development Zone in Zhejiang Province. It is 5 kilometers north of Wenzhou Longwan International Airport, 15 kilometers west of the Wenzhou Bridge Expressway entrance, and easily accessible via major roads such as Ouhai Avenue and Airport Avenue, providing convenient transportation and an excellent geographical location.

Pingyang Tianwei Machinery Co., Ltd. specializes in the production of various bolt cold heading machines. The company manufactures cold heading machines ranging from M6 to M30, including 3-die 3-blow, 4-die 4-blow, 5-die 5-blow, and 6-die 6-blow configurations, as well as extended and multi-station cold heading machines. These machines are widely used in the production of furniture screws, automotive and motorcycle parts, national standard bolts, power bolts, steel structure bolts, and non-standard bolts. The company possesses cold heading molding design and manufacturing technology that meets international standards, supported by experienced and innovative technical talent and advanced product processing equipment.

Product Advantages:

The products are known for their high precision, energy efficiency, rational structure, ease of maintenance, user-friendly operation for both new and existing customers, and excellent cost-performance ratio. The products enjoy a strong reputation within the industry. Tianwei Machinery also offers customized solutions tailored to meet various customer needs.

The company adheres to the principle of “survival through quality, development through service,” continuously improving product quality and innovating to create new high-tech products that satisfy customer needs. With comprehensive after-sales service, we eliminate customers’ concerns. Pingyang Tianwei Machinery Co., Ltd. is committed to working closely with new and old customers from both domestic and overseas markets to create a prosperous future together.

Guangdong Taijishan Technology Co., Ltd.

Booth: 3D620

Established in 2009, Guangdong Taijishan Technology Co., Ltd. is a well-known enterprise with over 20 years of experience in mechanical research, development, and manufacturing. The company specializes in producing precision guide pillar-type high-speed punching machines, elbow-type high-speed precision punching machines, high-speed precision cold heading machines, and nut machines. Its research and development department brings together numerous industry elites, forming a high-end, precise, and cutting-edge technical team. The company has established a technological innovation model combining production, academia, and research. It has been awarded several authoritative certifications, including the "China Brand Cultivation Certificate," "Management Quality Certification," and "High-tech Enterprise" certification.

The company focuses on the high-end precision stamping and user demands, researching core technologies, materials, processes, and designs to develop and produce high-end, high-speed precision stamping and cold heading equipment. Some of the equipment, which includes the domestic first innovation in high-speed precision stamping, successfully fills gaps in the domestic market. The company has imported advanced inspection and processing equipment from Italy and Japan, enabling the production of more complex and precise machines. These core components contribute to the development of China's high-speed precision stamping and cold heading industry.

The company adheres to the business philosophy of "people-oriented, mutual benefits," earning widespread praise from customers. Taijishan also has sales bases in countries such as Thailand, Vietnam, and India.

Dongguan Ansheng Hardware Machinery Co., Ltd.

Booth: 3C302

Dongguan Ansheng Hardware Machinery Co., Ltd. is a joint venture between Taiwan and mainland China, specializing in hardware machinery. The company operates a hardware machinery division that deals with new tools, fastener nut forming machines, automatic lathes, CNC lathes, thread rolling machines, and automatic bar feeders. Additionally, the company has established branches in various regions, including Zhejiang, Wenzhou, and Kunshan, and operates a hardware factory focused on mechanical repair, after-sales service, and hardware processing.

The company adheres to the principle of "quality assurance and service first" and, with years of experience in the production and distribution of the above machinery, leverages its strong technical capabilities to provide high-quality service to customers.

Hebei Wuhe Machinery Manufacturing Co., Ltd.

Booth: 3C202

Hebei Wuhe Machinery Manufacturing Co., Ltd. is a professional manufacturer of fastener forming machines and multi-station cold heading machines. The company is located in the Huanghua Port area — Huanghua City, Hebei Province, with convenient transportation links.

The company is staffed with core industry technical personnel and a research and development team, with years of rich experience and deep understanding of cold heading machines. By continuously innovating to meet the recognition of customers and operators, and through strict quality control, the company reduces after-sales service costs, lowers production costs, and improves production efficiency, achieving a win-win outcome.

The company’s product range is complete, including models from 11B6S to 41B6S, covering standard types, extended models, and top-die ejection types. Custom machines can also be designed according to customer requirements to achieve production goals. The company always adheres to the core values of "people-oriented, innovation, honesty, and teamwork" to provide customers with "practical, easy-to-use, and durable" products.

From product introduction and technical communication to after-sales service, the company ensures meticulous and thoughtful service throughout the entire process, striving to build itself into a leading brand in the domestic cold heading machine industry.

Ningbo Tianxiang Machinery Co., Ltd.

Booth: 3E102

Ningbo Tianxiang Machinery Co., Ltd. is located in the Binhai Economic Industrial Zone of Cixi City, Zhejiang Province. It is a professional manufacturer specializing in high-end precision cold heading machines. The company’s General Manager, Mr. Zhu Junxiao, has over 20 years of experience in the machinery industry and more than a decade of expertise in the design and development of cold heading machines. He has successfully developed over 50 models of cold heading machines ranging from M1 to M30 and from 2-die to 8-die stations. Notably, he independently invented the first and only zero-clearance slider cold heading machine in China, filling a key gap in the domestic precision cold heading machine market. Mr. Zhu also brings nearly ten years of experience in managing medium to large-scale enterprises.

Tianxiang-branded high-end precision cold heading machines are equipped with world-class pneumatic, hydraulic, electrical, and control systems. The company adheres to a design philosophy that emphasizes reliability, professionalism, and user-friendliness. It enforces strict control throughout the entire process—from machining and inspection to assembly—to deliver first-class products and services from mainland China.

Ningbo Tianxiang maintains a moderate production scale to ensure steady development, striving for elite-level quality and excellence in every cold heading machine produced. With a strong R&D and design innovation capability, the company continues to offer customized machines tailored to meet diverse product and application needs.

With outstanding quality, professional service, and solid technical assurance, Tianxiang is committed to working hand in hand with clients around the world to build a better future. "Dedication brings achievement" is the company’s guiding principle. We warmly welcome inquiries and visits from both new and long-standing customers at home and abroad.

Zhejiang Baotuo Machinery Co., Ltd.

Booth: 3D008

Zhejiang Baotuo Machinery Co., Ltd., established in 2006, is a technology-oriented enterprise specializing in the development, design, and manufacturing of screw heading machines, thread rolling machines, and multi-station cold heading forming machines. The company is located in the Yaozhuang Economic Development Zone, Jiashan County, Zhejiang Province, covering an area of 30,000 square meters, with fixed assets totaling 150 million RMB.

Baotuo boasts a strong R&D team, with 8 in-house engineers and 15 technical personnel. Since its founding, the company has built a complete processing system and developed advanced process technologies. Baotuo’s products integrate cutting-edge technologies from Japan and Taiwan, along with advanced German design concepts. Key features include variable frequency speed control systems, adjustable V-shaped guide rails, and automatic metered oil lubrication systems. The lubrication and cooling systems have been fundamentally improved, ensuring better equipment stability and control while significantly extending service life. In terms of structural design and performance, Baotuo’s machines surpass traditional counterparts, representing a major innovation in the industry.

Since its inception, the company has developed over 30 models of medium- to high-speed screw and bolt forming machines, including 1-die 2-blow, 2-die 2-blow, 3-die 3-blow, and 4-die 4-blow machines, as well as high-speed thread rolling machines. It also customizes non-standard heading machines based on customer requirements. With a commitment to quality and integrity, Baotuo uses highly wear-resistant alloy cast iron and imported special alloy materials, equips machines with Japanese electrical control systems, and adopts high-end CNC machining processes along with Taiwanese assembly techniques. Professional after-sales service further supports its customer base.

Baotuo has developed into a specialized manufacturer of precision fastener equipment, earning high praise from both domestic and international clients. Its products are widely sold across regions such as Jiangsu, Zhejiang, Shanghai, Guangdong, Tianjin, Hebei, Shandong, Jiangxi, and Chongqing, and are also exported to countries including Turkey, Russia, India, and Iran.

Zhejiang Shengtuo Machinery Co.,Ltd.

Booth: 3F502

Zhejiang Shengtuo Machinery Co., Ltd. is a specialized manufacturer of multi-station cold heading machines for fastener production. The company operates a modern facility with a total floor area of 7,600 square meters and employs dozens of engineering and technical professionals. Over the years, Shengtuo has accumulated extensive practical experience in production technology, offering advanced processes, a complete product lineup, and well-equipped manufacturing systems. The company is committed to delivering stable product quality and ensures a 100% pass rate for all machines before they leave the factory—earning widespread praise from domestic users.

Currently, the company has over 70 employees across five key departments: machine building, quality assurance, research and development, sales, and management. With a philosophy rooted in precision, excellence, and customer-first service, the company provides comprehensive support to its clients. Driven by a spirit of continuous improvement and innovation, Shengtuo adheres to the principle of "survival through quality, development through credibility" and looks forward to building sincere partnerships with both new and existing customers to create a better future together.

Shengtuo’s flagship products are multi-station cold heading forming machines, many of which are protected by patents. With a full range of models and consistently high quality, the company’s products are widely sold across China and exported to Southeast Asia, the Middle East, the Americas, and other regions—earning strong recognition from customers worldwide.

Dongguan Jinqi Hardware Machinery Co., Ltd.

Booth: 3C318

Jinqi Industrial Co., Ltd. was established in Luzhu, Kaohsiung, Taiwan. With its professional manufacturing expertise and strict quality control, the company specializes in designing and producing complete sets of screw manufacturing equipment. By leveraging the experience of industry elites, employing advanced inspection facilities, and adhering to rigorous scientific production and QC management systems, Jinqi continuously develops and innovates to deliver machinery characterized by high productivity, high precision, and high stability. Its products are well-received by users both domestically and internationally.

To better serve its mainland Chinese customers, Jinqi began expanding into the mainland market in 1998. Upholding the business philosophy of "Integrity, Professionalism, Pragmatism, and Innovation" and the principle of "Customer First for Quality Products; People-Oriented for Shared Success," the company has actively developed the domestic market. It has successively established distribution and after-sales service centers in Dongguan, Shanghai, Suzhou, and Ningbo to provide each customer with faster, higher-quality, and more comprehensive after-sales support.

Please first Loginlater ~